+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

PP Uniaxial Geogrid – Geofantex

- Brand GeoFanGrid® PPS

- Product origin China

- Delivery time 7-14 days

- Supply capacity 40′ HQ/ 7 Days

Product Details

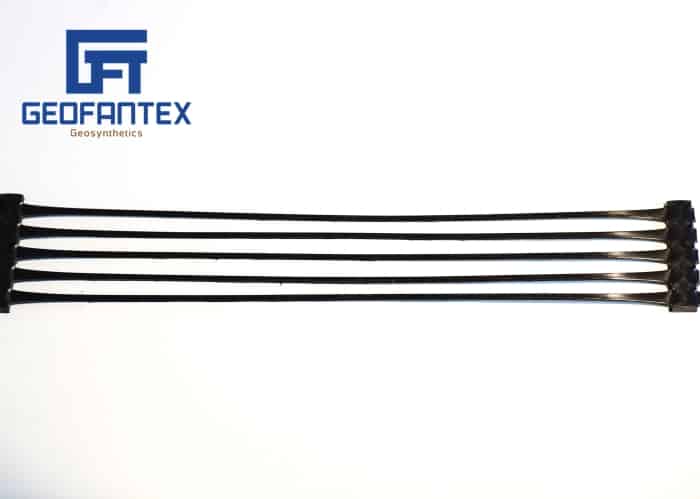

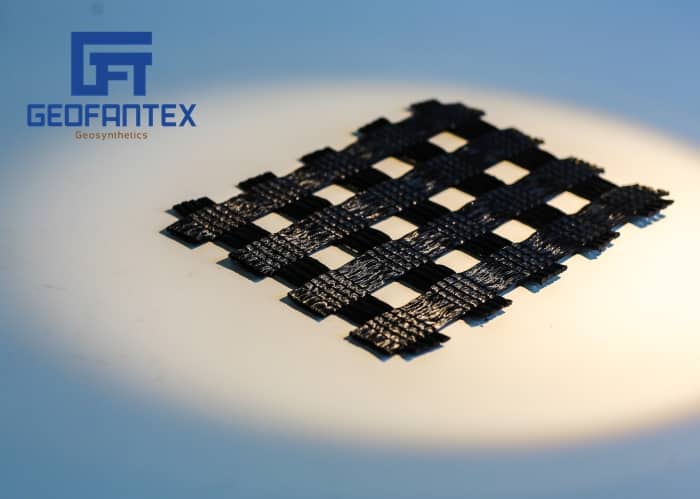

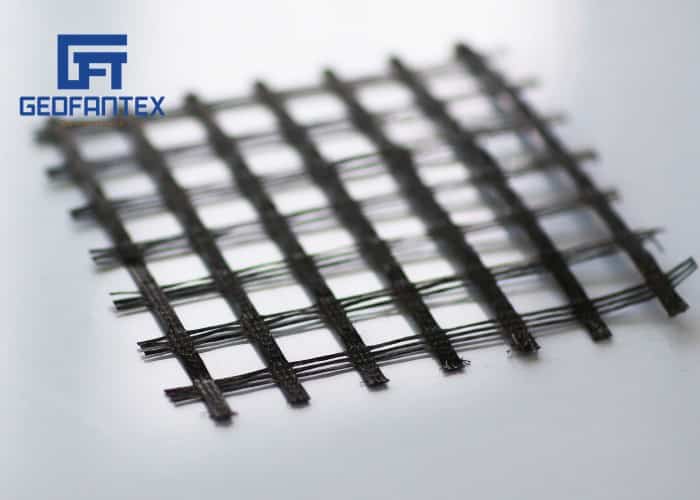

PP Uniaxial Plastic Geogrid – GeofanGrid PPS

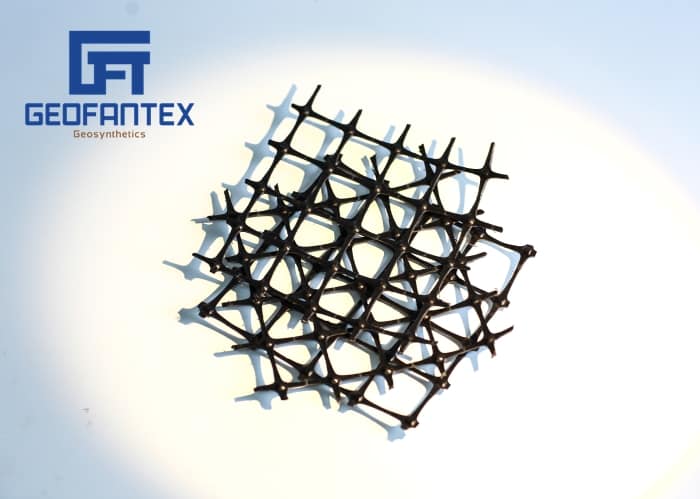

PP Uniaxial Plastic Geogrid (GeofanGrid PPS) is manufactured from the most proven “punch-and-drawing” techniques with the most sophisticated manufacturing technology. Solid sheets of polymer have apertures removed by punching, and then the sheet is carefully stretched to achieve optimum molecular orientation within the monolithic polymer structure. Therefore high ultimate tensile strengths of up to 300kN/m can be achieved. PP Uniaxial Plastic Geogrid (GeofanGrid PPS) is manufactured from High-Density Polyethylene. HDPE Uniaxial Plastic Geogrid (GeofanGrid PPS) is manufactured through the process of extruding the sheet, punching the designed holes, and heating while longitudinal stretching.

The Properties of PP Uniaxial Plastic Geogrid (GeofanGrid PPS)

( Plastic geogrids are many kinds according to the specifications, such as multiple geogrids, and single geogrids, please click the other PP plastic geogrid. MINIMUM ORDER QUANTITY: 20’ft Container)

| Properties [ASTM D 6637] | Unit | PPS60 | PPS80 | PPS110 | PPS150 | PPS260 | PPS300 |

| Tensile Strength | ≥KN/M | 60 | 80 | 110 | 150 | 260 | 300 |

| Strength at 2% Elongation | KN/M | 17 | 26 | 32 | 45 | 94 | 105 |

| Strength at 5% Elongation | KN/M | 35 | 48 | 65 | 90 | 185 | 195 |

| Yield Elongation Ratio | ≤% | 10 | 10 | 10 | 10 | 10 | 10 |

The Applications of PP Uniaxial Plastic Geogrid – Geofantex

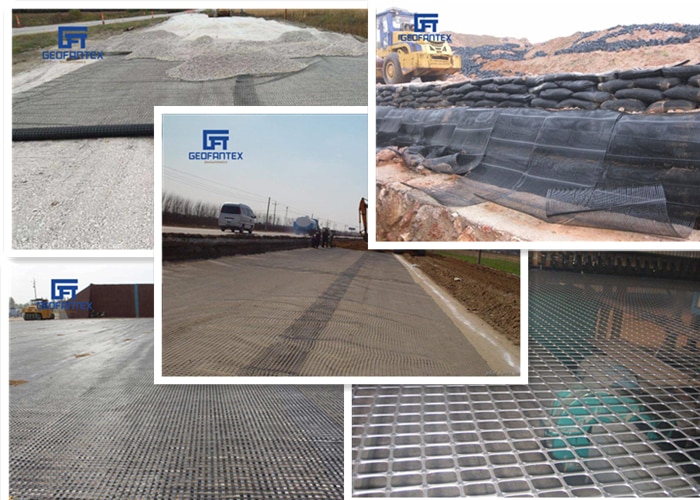

The unidirectional plastic geogrid is a high-strength geosynthetic material. It is widely used in dams, tunnels, wharves, highways, railways, construction, and other fields.

PP Uniaxial Plastic Geogrid Role in engineering – Geofantex

- Strengthen the roadbed, which can effectively distribute the diffusion load, improve the stability and bearing capacity of the roadbed, and prolong the service life;

- Can withstand greater alternating loads;

- Prevent roadbed deformation and cracking caused by the loss of roadbed materials;

- Improve the self-supporting capacity of the fill behind the retaining wall, reduce the earth pressure of the retaining wall, save costs, extend the service life, and reduce maintenance costs;

- Combining the spray-anchored concrete construction method for slope maintenance can not only save 30%-50% of the investment but also shorten the construction period by more than one time;

- Adding a geogrid to the roadbed and surface layer of the highway can reduce deflection, reduce rutting, delay the appearance of cracks by 3-9 times, and reduce the thickness of the structural layer by 36%;

- Applicable to all kinds of soil, no need to obtain materials from other places, saving labor and time;

- The construction is simple and quick, which can greatly reduce the construction cost.

Geofantex Geosynthetics has to make a series of guarantees for our products both plant processing and selling out to our customers. Selling to you is the first step, the service and guarantee are our task. Geofantex Geosynthetics has an ISO Certificate to guarantee the raw material, the product processing, and the end product. From receiving your order to the replacement and installation of the products, we have solved the problems in time if you need them, whatever the quality and technical guidelines or suggestions. Our company has been committed to supplying high-quality products at reasonable prices and delivery on time.

GEOFANTEX has an on-site Manufacturing Quality Assurance Laboratory at the factory. GEOFANTEX maintains a high level of quality and up-to-the-minute results on finished products through a fully equipped, well-staffed, dedicated laboratory existing in each of the manufacturing facilities. Each facility follows the same guidelines for evaluating the quality of GEOFANTEX products and is capable of adapting to market-driven requirements.

A. Objective

The objective of the GEOFANTEX Quality Assurance program is to define the implementation of basic manufacturing quality assurance (MQA) procedures necessary to ensure the consistent production of quality products supplied to the geosynthetic market. Note that at this time, these procedures are limited to Uniaxial Plastic Geogrid.

B. Scope

To achieve GEOFANTEX’s stated purpose, a rigorous set of minimum standards and an effective test program to assure compliance have been established. These procedures and requirements are frequently reviewed and adjusted to assure compliance with current market demands and/or predetermined project specifications. These procedures ensure that raw materials and process parameters are controlled to provide products complying with GEOFANTEX’s pre-defined minimum characteristics.

Uniaxial Plastic Geogrid PRODUCT IDENTIFICATION AND DOCUMENTATION

A. Roll Numbering

Each roll of Uniaxial Plastic Geogrid is assigned a unique roll number. The Quality Assurance Laboratory maintains records documenting the raw materials and resulting product quality information.

B. Approval Procedure

Results for each tested roll of the product are checked against both GEOFANTEX China standard and customer specifications for compliance. The Quality Assurance Laboratory approves those materials that meet these requirements for shipment.

C. Non-Conformance

Material that does not meet GEOFANTEX minimum standards is given a roll number but is rejected and not placed into inventory. The material is identified as scrap and will not be utilized. Material that meets GEOFANTEX minimum standards but does not meet a stricter customer specification is not allocated to that customer but is placed into inventory as GEOFANTEX standard material.

D. Documentation

Individual Quality Assurance Certificates are generated and supplied for each roll of Uniaxial Plastic Geogrid product to include all relevant quality assurance information about the material(s).

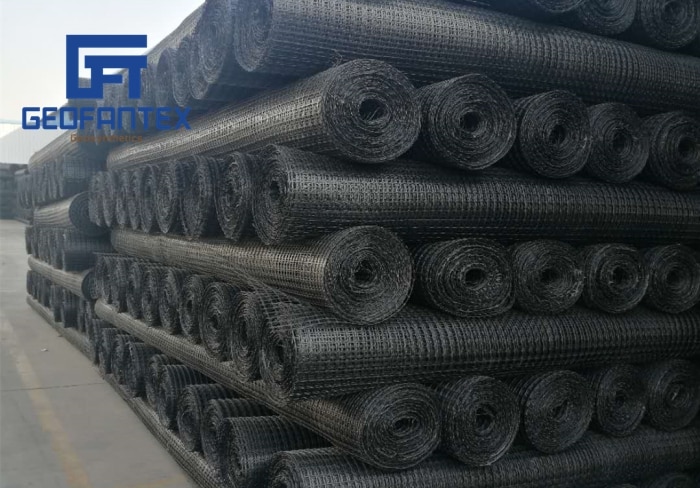

Geofantex Geosynthetics has a series of package and delivery service working procedures. Geofantex Geosynthetics has supplied thousands of containers to Latin America, North America, Southeast Asia developed countries, and Africa within the past ten years. We provide the package of products with the rolls, pots, bags, sheets, or your requirement in orders. Our company has been committed to supplying high-quality products at reasonable prices and delivery on time. Delivery of one 40’HQ within 7 – 10 days. And we should increase loading quantity and make you save the freight costs maximumly. We supply the products by plane, by sea, and by land carriage to any region or any country worldwide, even the door-to-door service.

| SEPARATION | REINFORCEMENT | FILTRATION | DRAINAGE | WATERPROOF | PREVENTION | POLLUTION PREVENTION | PROTECTION | CONSOLIDATE | |

| GEOTEXTILE | √ | √ | √ | √ | √ | √ | |||

| GEOMEMBRANE | √ | √ | √ | ||||||

| GEOGRID | √ | √ | |||||||

| GEONET | √ | ||||||||

| GEOTUBE | √ | ||||||||

| GEOCELL | √ | √ | |||||||

| GCL | √ | √ | |||||||

| GEOCOMPOSITE | √ | √ | √ | √ | √ | √ | √ |

What is PP Uniaxial Plastic Geogrid – GeofanGrid® PPS

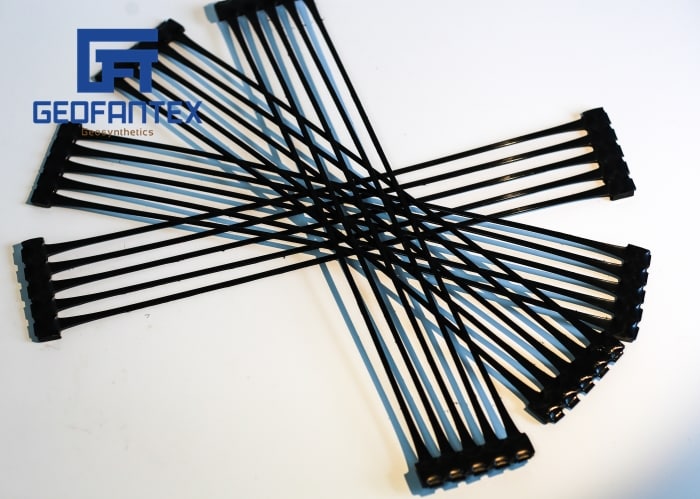

The uniaxial grid is only stretched along the length of the sheet, while the biaxial stretch grid is made by continuing to stretch the unidirectional stretched grid in the direction perpendicular to its length.

In the manufacture of the plastic geogrid, the polymers of the polymer will be rearranged and oriented during the heating and extension process, which strengthens the bonding force between the molecular chains and achieves the purpose of improving its strength. Its elongation is only 10% to 15% of the original sheet. If anti-aging materials such as carbon black are added to the geogrid, it can make it have better durability such as acid resistance, alkali resistance, corrosion resistance, and aging resistance.

What are the three types of geogrid?

There are four types of geogrids Uniaxial, Biaxial, Triaxial and Geogrid-Geotextile Composites.

Where is geogrid placed?

How is geogrid installed? Once the subgrade material (that’s the layer under everything else) is prepared, a geogrid is placed on top (sometimes along with a geotextile filter fabric used to keep fine material from migrating into the aggregate base).

What are the different types of geogrid?

Geogrid is used in numerous civil engineering related applications to reinforce soils. It has high tensile strength which allows it to transfer forces across a larger area of soil than otherwise would be the case. There are three types; uniaxial, biaxial, and triaxial.

Development history of the Geofantex

2014 — Geofantex Geosynthetics Co., Ltd. Factory was established

2015 — promoting the new image and building GeoFanTex brand

2018 — Geofantex products exceeded 100 million dollar

2019 — Upgrade new nonwoven geotextile, Geomembrane, and Composite geomembrane production line.

2020 — The new factory was completed.

2021 — Upgraded production line of the factory, making all the products could meet ASTM, AS, and ISO standards.

2022— Improve the quality of after-sales service and launch customized products.

Company Profile

Geofantex Geosynthetics Co., Ltd. is located in the beautiful coastal city of Dalian, with superior geographical location, convenient transportation, and developed communications. The company was founded in 2014 with a registered capital of 5,000,000 yuan. It has an industrial park covering an area of more than 50 acres in Jinan, Shandong. It has a modern office environment, advanced production equipment, and a group of high-quality and professional technical and management personnel.

The company gives full play to its own innovation advantages, platform advantages, and market advantages, and with the support of national policies, builds a national first-class enterprise, always follows the principle of “quality first, reputation first”, adhering to the principle of “people-oriented, quality for survival, integrity, unity and hard work”, Integrated enterprise spirit, sincere cooperation with various engineering units and colleagues from all walks of life, harmonious development, and work together to make greater contributions to infrastructure.

Get the latest price?

We’ll respond as soon as possible(within 12 hours)