+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Drainage Geonet – Geofantex

- Brand GeoFanNet® Geonet

- Product origin China

- Delivery time 7-14 days

- Supply capacity 40′ HQ/ 7 Days

Product Details

Drainage Geonet – Geofantex

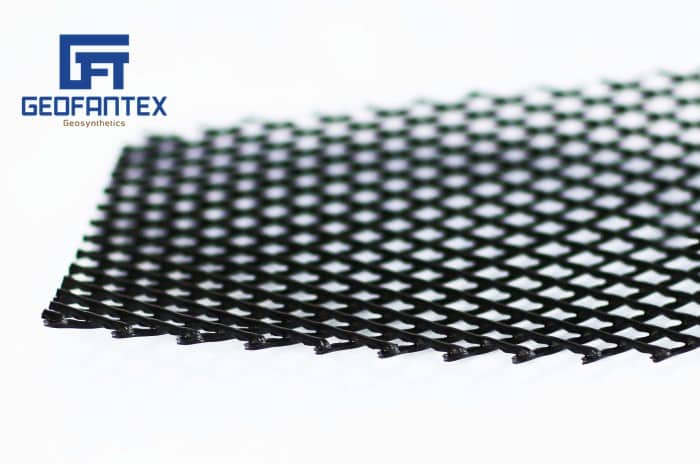

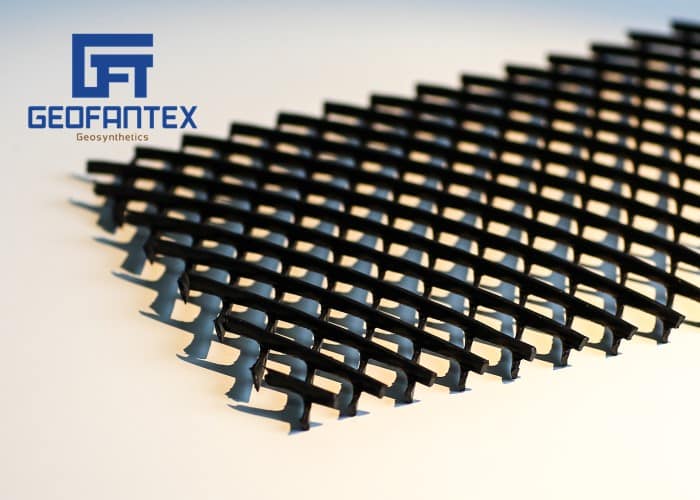

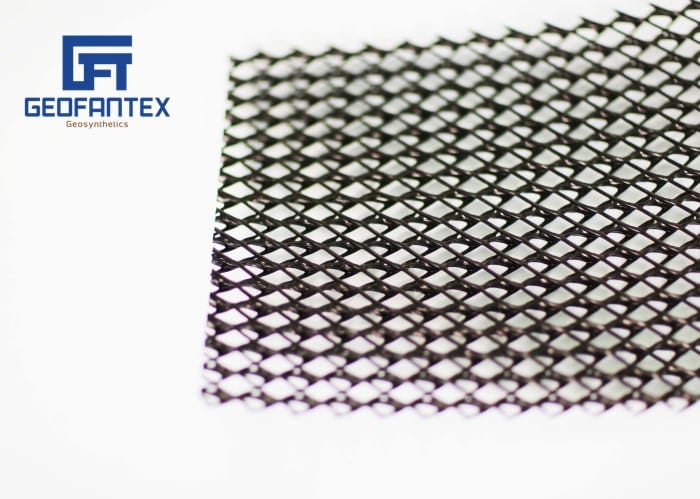

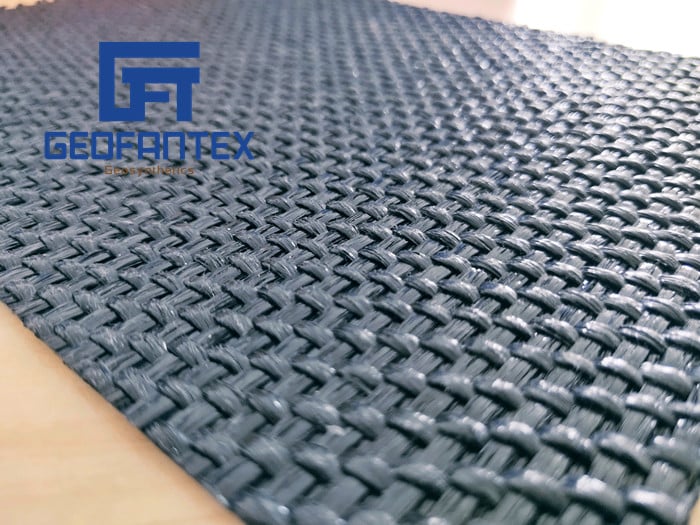

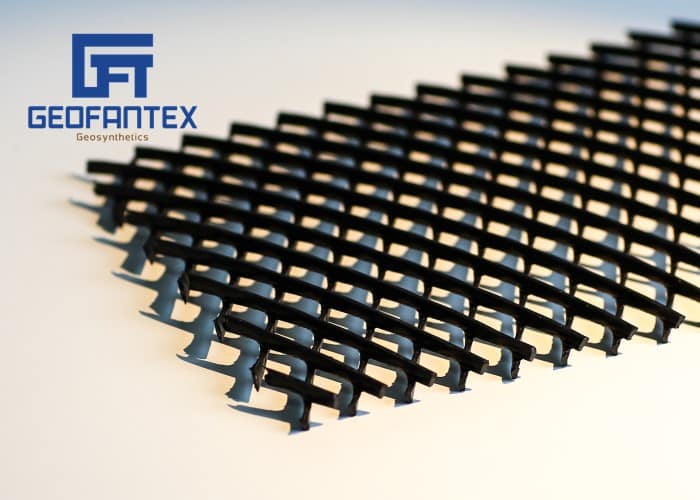

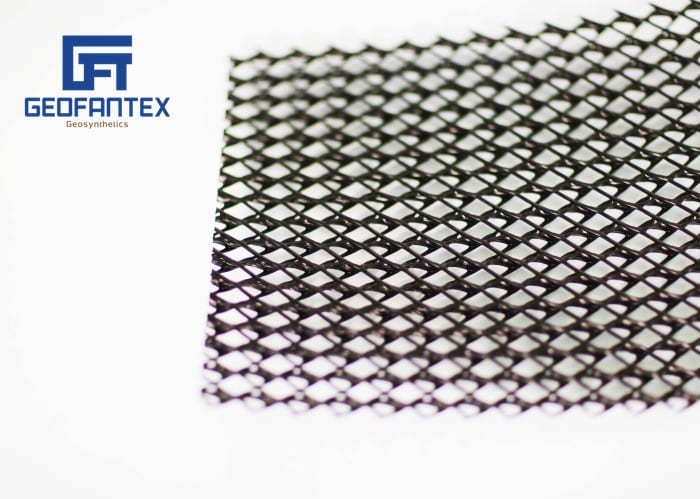

Drainage Geonet is a bi-planar or tri-planner geonet with two sets of diagonally parallel-crossing HDPE strips in a round cross-sectional shape. This unique strips structure provides superior compressive creep resistance and ensures continuous flow performance over a broad range of conditions and long durations.

The lightweight and flexible Bi-Planar or tri-planar Geonet is easy to install and has long-term durability. Available in a range of sizes, Bi-planar Geonet can be suited for projects where the foundation is reasonable or the bearing capability demand is low.

Geonets are among the most proven geosynthetics drainage systems. Manufactured from two, or three strands of extruded HDPE which are overlayed across each other, this material forms a void within which water can be transmitted and reduces pore water pressure.

Could be manufactured according to your inquiry, MINIMUM ORDER QUANTITY: 20’ft Container

| Mechanical Properties [Test Standard] | Unit | Specification |

| Mass Per Unit Area [ASTM D5261] | g/m2 | 660 |

| Thickness [ASTM D5199] | mm | 4.97 |

| Strip Tensile Strength [ASTM D5035] | kN/m | 7.57 |

The Applications of Drainage Geonet – Geofantex

- Used to stabilize road and railway subgrades.

- The anti-seepage of municipal engineering, underground engineering of subways, buildings and roof reservoirs.

- Environmental protection and sanitation, domestic waste landfill, sewage treatment plant, Prevent cracks in the roadbed and avoid landslides.

- Strengthen the foundation, the slope of the embankment, improve the stability of the roadbed, and reduce the area occupied;

- It can bear heavy loads;

- Shorten the construction period of the project; the specifications and performance parameters of the geonet can also be constructed under harsh environmental conditions.

- It is used for pavement reinforcement, so that the grid and pavement materials can be integrated together, which can effectively disperse and transmit the load and prevent road cracks.

Drainage Geonet Role in engineering – Geofantex

- It has excellent waterproof and anti-seepage performance, the anti-seepage hydrostatic pressure can reach 1.0MPa or more, and the permeability coefficient is 5×10-9cm/s. Bentonite is a natural inorganic material, which will not cause an aging reaction and has good durability

- Lay between the foundation and the foundation to drain the accumulated water between the foundation and the foundation, block the capillary water and effectively integrate it into the edge drainage system. This structure automatically shortens the drainage path of the foundation, greatly reduces the drainage time, and can reduce the use of selected foundation materials (that is, materials with more fine materials and lower permeability can be used). Can extend the service life of the road.

- Laying drainage nets on the sub-base layer can prevent the fine materials from the sub-base layer from entering the base layer (that is, it acts as isolation). The aggregate base layer will enter the upper part of the geonet to a limited extent. In this way, the composite geotechnical drainage net also has the potential function of restricting the lateral movement of the aggregate base layer. In this way, its function is similar to the reinforcement function of the geogrid. Generally speaking, the tensile strength and rigidity of composite geotechnical drainage nets are better than many geogrids used for foundation reinforcement, and this restriction will improve the supporting capacity of foundations.

- After the road is aging and cracks are formed, most of the rainwater will enter the section. In this case, the drainage net is laid directly under the road surface instead of the drainage foundation. The drainage net can collect water before it enters the foundation/subbase. Moreover, a film can be wrapped on the bottom of the drainage net to further prevent moisture from entering the foundation. For rigid road systems, this structure allows the design of roads with a higher drainage coefficient Cd. Another advantage of this structure is that it may hydrate the concrete more uniformly (research on the extent of this advantage is ongoing). Regardless of whether it is a rigid road or a flexible road system, this structure can extend the service life of the road.

- In the northern climate, laying drainage nets can help reduce the impact of frost heave. If the freezing depth is very deep, the geonet can be laid on a shallower position in the base as a capillary block. In addition, it is often necessary to replace it with a granular base layer that is not susceptible to frost heaving, extending downward to the depth of freezing. The backfill that is easy to frost heave can be directly filled on the surface of the drainage net to the ground line of the foundation. In this case, the system can be connected to the drainage outlet so that the groundwater level is at or below this depth. This can potentially limit the development of ice crystals, and there is no need to limit the traffic load when the ice melts in the cold region in spring.

Geofantex Geosynthetics have to make a series of guarantee for our products both plant processing and selling out to our customers. The selling to you is the first step, the service and guarantee is our task. Geofantex Geosynthetics have an ISO Certificate to guarantee the raw material, the product processing, and the end product. From receiving your order to replacement and installation of the products, we have solved the problems in time if you need, whatever the quality and technics guideline or suggestions. Our company has been committed to supplying high-quality products with reasonable price and delivery in time.

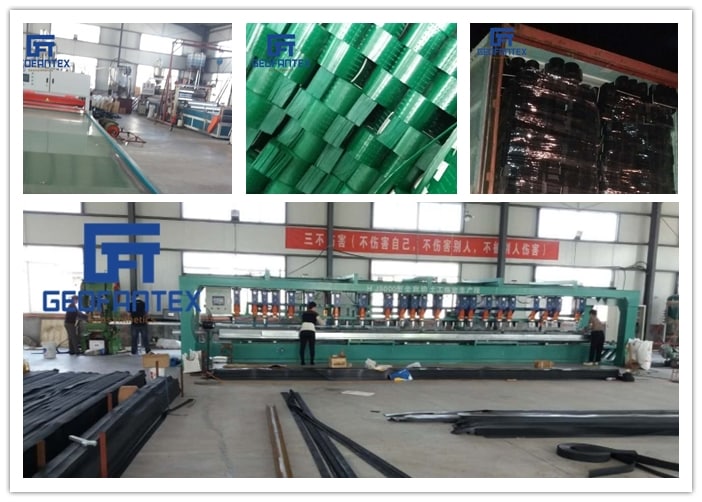

GEOFANTEX has an on-site Manufacturing Quality Assurance Laboratory at the factory. GEOFANTEX maintains a high level of quality and up-to-the-minute results on finished products through a fully equipped, well-staffed, dedicated laboratory existing in each of the manufacturing facilities. Each facility follows the same guidelines for evaluating the quality of GEOFANTEX products and is capable of adapting to market-driven requirements.

A. Objective

The objective of the GEOFANTEX Quality Assurance program is to define the implementation of basic manufacturing quality assurance (MQA) procedures necessary to ensure the consistent production of quality products supplied to the geosynthetic market. Note that at this time, these procedures are limited to Drainage Geonet.

B. Scope

In order to achieve GEOFANTEX’s stated purpose, a rigorous set of minimum standards and an effective test program to assure compliance have been established. These procedures and requirements are frequently reviewed and adjusted to assure compliance with current market demands and/or predetermined project specifications. These procedures assure that raw materials and process parameters are controlled to provide products complying with GEOFANTEX’s pre-defined minimum characteristics.

Drainage Geonet PRODUCT IDENTIFICATION AND DOCUMENTATION

A. Roll Numbering

Each roll of drainage geonet is assigned a unique roll number. The Quality Assurance Laboratory maintains records documenting the raw materials and resulting product quality information.

B. Approval Procedure

Results for each tested roll of the product are checked against both GEOFANTEX China standard and customer specifications for compliance. The Quality Assurance Laboratory approves those materials that meet these requirements for shipment.

C. Non-Conformance

Material that does not meet GEOFANTEX minimum standards is given a roll number but is rejected and not placed into inventory. The material is identified as scrap and will not be utilized. Material that meets GEOFANTEX minimum standards but does not meet a stricter customer specification is not allocated to that customer but is placed into inventory as GEOFANTEX standard material.

D. Documentation

Individual Quality Assurance Certificates are generated and supplied for each roll of Drainage Geonet product to include all relevant quality assurance information about the material(s).

Geofantex Geosynthetics have a series of package and delivery service working procedures. Geofantex Geosynthetics have supplied thousands of containers to Latin America, North America, Southeast Asia, and developed countries, and Africa within the past ten years. We provide the package of products with the rolls, pots, bags, sheets, or your requirement in orders. Our company has been committed to supplying high-quality products with reasonable price and delivery in time. Delivery one 40’HQ within 7 – 10 days. And we have an obligation in increasing loading quantity and make you save the freight costs maximumly. We supply the products by plane, by sea and land carriage to any regions or any countries of the worldwide, even the door-to-door service.

| SEPARATION | REINFORCEMENT | FILTRATION | DRAINAGE | WATERPROOF | PREVENTION | POLLUTION PREVENTION | PROTECTION | CONSOLIDATE | |

| GEOTEXTILE | √ | √ | √ | √ | √ | √ | |||

| GEOMEMBRANE | √ | √ | √ | ||||||

| GEOGRID | √ | √ | |||||||

| GEONET | √ | ||||||||

| GEOTUBE | √ | ||||||||

| GEOCELL | √ | √ | |||||||

| GCL | √ | √ | |||||||

| GEOCOMPOSITE | √ | √ | √ | √ | √ | √ | √ |

CERTIFICATES

What is Drainage Geonet – Geofantex

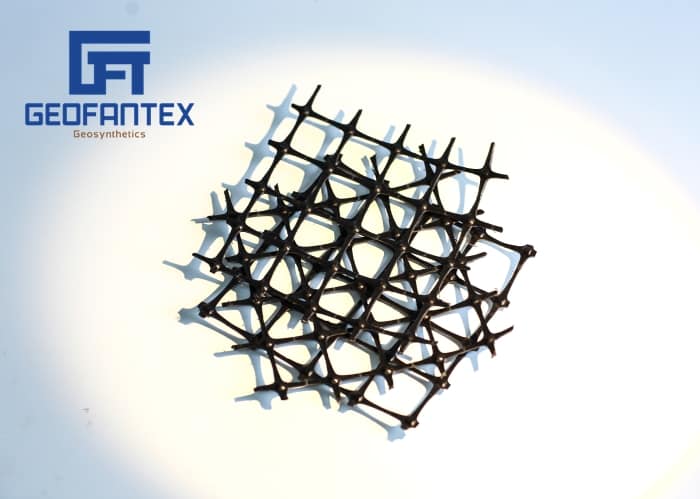

The geonet is a mesh geosynthetic material with a large perforation, a plane structure or a three-dimensional structure that is woven from synthetic material strips, thick strands or pressed by synthetic resin. It is used for soft foundation reinforcement cushion, slope protection, grass planting and as a base material for the manufacture of combined geotechnical materials.

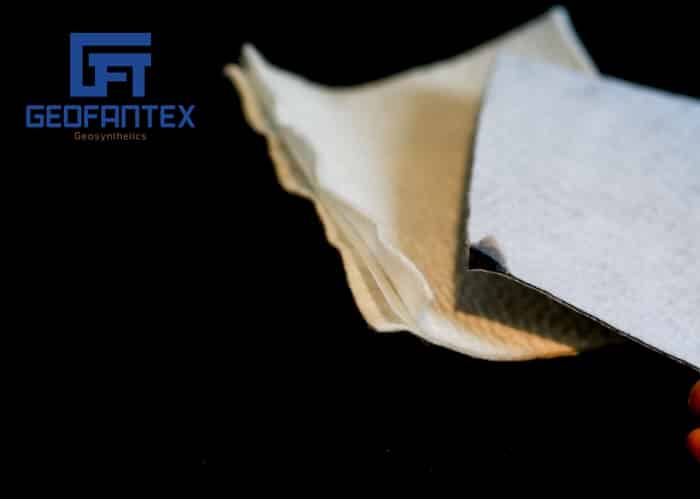

In transportation infrastructures such as railways and highways, the safety and service life of the project is closely related to its own drainage system. Geosynthetics is an important part of the drainage system. The drainage geonet in the drainage net is a new type of geosynthetic material. The composition structure is a three-dimensional geonet core with needle-punched non-woven geotextiles on both sides. The drainage geonet core consists of a thick vertical rib and an inclined rib on the top and bottom. It can quickly discharge groundwater from the road, and it also has a pore maintenance system that can block capillary water under high loads. At the same time, it can also play a role in isolation and foundation reinforcement. A new type of geosynthetic material

Development history of the Geofantex

2014 — Geofantex Geosynthetics Co., Ltd. Factory was established

2015 — promoting the new image and building GeoFanTex brand

2018 — Geofantex products exceeded 100 million dollar

2019 — Upgrade new nonwoven geotextile, Geomembrane, and Composite geomembrane production line.

2020 — The new factory was completed.

2021 — Upgraded production line of the factory, making all the products could meet ASTM, AS, and ISO standards.

2022— Improve the quality of after-sales service and launch customized products.

Company Profile

Geofantex Geosynthetics Co., Ltd. is located in the beautiful coastal city of Dalian, with superior geographical location, convenient transportation, and developed communications. The company was founded in 2014 with a registered capital of 5,000,000 yuan. It has an industrial park covering an area of more than 50 acres in Jinan, Shandong. It has a modern office environment, advanced production equipment, and a group of high-quality and professional technical and management personnel.

The company gives full play to its own innovation advantages, platform advantages, and market advantages, and with the support of national policies, builds a national first-class enterprise, always follows the principle of “quality first, reputation first”, adhering to the principle of “people-oriented, quality for survival, integrity, unity and hard work”, Integrated enterprise spirit, sincere cooperation with various engineering units and colleagues from all walks of life, harmonious development, and work together to make greater contributions to infrastructure.

Get the latest price?

We’ll respond as soon as possible(within 12 hours)