Geofantex Blog

+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geosynthetics products information and Technology

The Impact of Geosynthetics on Infrastructure and Environmental Conservation Efforts

In the realm of civil engineering and environmental science, geosynthetics, which are polymeric (plastic) man-made products used to solve geotechnical problems in construction projects, have emerged as a cornerstone technology,…

From Erosion Control to Water Management: The Versatility of Geonets

Geonets represent a revolutionary stride in the field of geotechnical engineering, offering robust solutions to some of the most pressing environmental and structural challenges of our times. These geosynthetic materials,…

Stabilizing Soils and Pavements: The Essential Role of Geosynthetics

In the realm of civil construction, the evolution of materials and methodologies has been pivotal in advancing the industry’s capability to tackle complex challenges. Among these innovations, geosynthetics have emerged…

How Geocell Reinforcement Transforms Weak Soils into Strong Foundations

In the quest for sustainable construction and land management solutions, geocell ground stabilization emerges as a groundbreaking technique. This innovative approach not only enhances soil stability but also champions environmental…

From Thickness to Resistance: Understanding HDPE Pool Liners

In the world of aquatic leisure and construction, the quest for durable, efficient, and eco-friendly materials is never-ending. The introduction of High-Density Polyethylene (HDPE) geomembrane as a pool liner material…

Efficient Water Management with Geocomposite Drainage Systems

In the realm of civil engineering and landscape architecture, efficient water management is crucial for sustainability and structural integrity. The geocomposite drainage system emerges as a pivotal solution, marrying the…

The Science of HDPE Geomembrane Liners: Material, Benefits, and Applications

In today’s environmentally conscious world, the protection of natural resources and the containment of hazardous materials have never been more important. One of the key players in this endeavor is…

Enhancing Soil Stability with Geocell Technology: A Guide to Modern Engineering Solutions

In recent years, the construction and civil engineering industries have increasingly turned to innovative solutions to address complex challenges in soil stabilization and reinforcement. Among these, geocell technology has emerged…

The Essential Guide to Geotextiles: Protection, Filtration, and Erosion Control

Geotextile ground cover, a term that might sound complex, is actually a revolutionary material that’s transforming how we interact with our natural landscape. At its core, geotextile is designed to…

Revolutionizing Ground Improvement: The Impact of Reinforcement Geosynthetics

In the world of civil engineering and construction, innovation and sustainability are paramount. Among the myriad of advancements, reinforcement geosynthetics stand out as a transformative solution for ground improvement. These…

The Future of Construction: Embracing Geosynthetic Technologies

In the modern era of infrastructure development, the integration of innovative materials and technologies has become pivotal in enhancing the longevity and efficiency of transportation systems. Among these advancements, geocell…

The Versatile World of Geomembrane Waterproofing: Applications & Benefits

In the quest for durable and effective waterproofing solutions, geomembrane waterproofing stands out as a technological marvel, safeguarding structures from the relentless assault of water. This advanced material, often hidden…

Revolutionizing Railway Construction: The Role of Geocell Technology

In the modern era of infrastructure development, the integration of innovative materials and technologies has become pivotal in enhancing the longevity and efficiency of transportation systems. Among these advancements, geocell…

Innovative Geocomposite Solutions for Enhanced Gas Containment

In the realm of environmental engineering and waste management, “geocomposite gas” systems are emerging as a pivotal technology for efficient gas filtration and containment. These innovative materials blend the functionality…

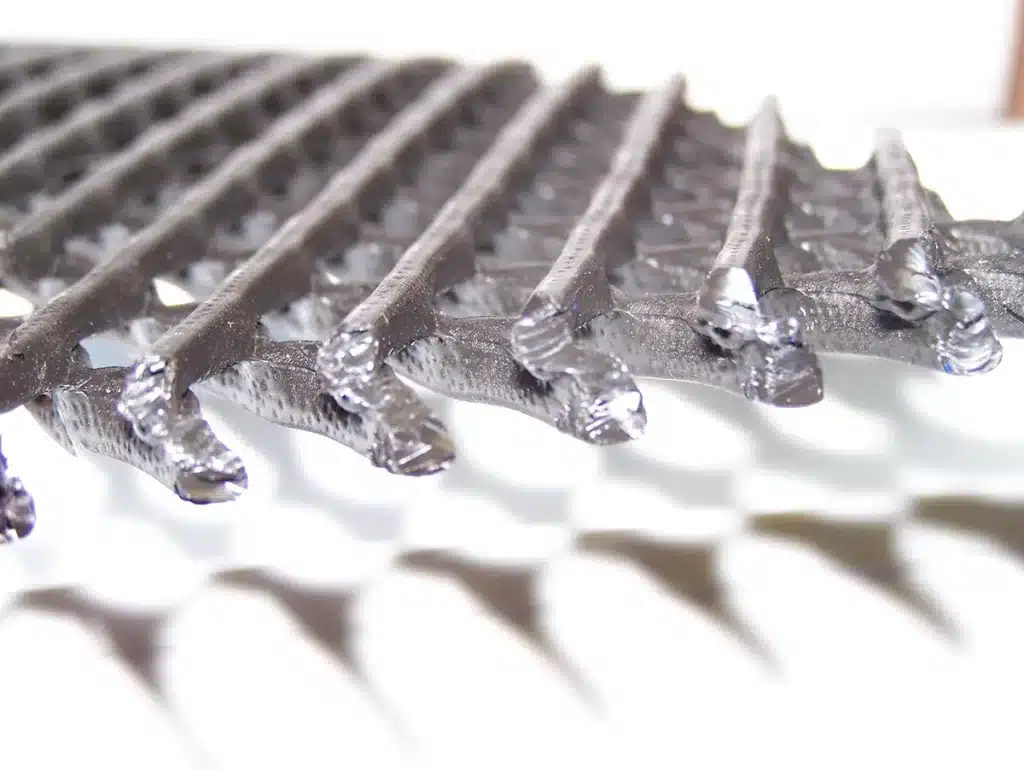

Unrolling the Potential: The Essential Guide to Geogrid Rolls

In the vast and ever-evolving field of civil engineering, the quest for materials that offer durability, flexibility, and cost-effectiveness has led to the innovation of geogrids. Geogrid rolls, in particular,…

Geocomposites in Waste: Enhancing Landfill Safety & Efficiency

In the quest for sustainable waste management solutions, the importance of efficient landfill design cannot be overstated. Among the myriad of technologies and materials employed to enhance the functionality and…

Water Safety with Advanced Geomembrane Technology

In our ongoing quest for sustainability and environmental preservation, containment pond geomembranes have emerged as a cornerstone technology. These innovative barriers are designed to protect our natural resources and ensure…

Stabilizing Slopes with Geocells: An Innovative Approach to Erosion Control

In the continuous battle against soil erosion and landscape degradation, innovative solutions are always in demand. Among these, geocell technology has emerged as a frontline defense, particularly in slope protection…

How to Determine the Durability of Geotextiles Through Tensile Testing

Geotextiles emerge as unsung heroes, reinforcing soil, aiding in erosion control, and enhancing durability. However, the core of their effectiveness lies in an attribute not visible to the naked eye:…

Stabilizing Slopes with Geocells: An Innovative Approach to Erosion Control

In the realm of construction and landscaping, the strength and longevity of structures are paramount. One technology that has revolutionized these sectors is geosynthetic reinforcement, a solution that not only…

Get the latest price?

We’ll respond as soon as possible(within 12 hours)